Dongkuk CM implements eco-friendly

policies to create sustainable values.

Dongkuk CM's efforts are still continuing:

Based on the electric furnace manufacturing method that produces new steel products using scrap metal as a recycled raw material,

all business sites strictly adhere to the principle of minimizing pollutant emissions and energy consumption, minimize environmental pollution through process improvement and facility investment, and at the same time, try to produce the best product quality.

Based on the electric furnace manufacturing method that produces new steel products using scrap metal as a recycled raw material,

all business sites strictly adhere to the principle of minimizing pollutant emissions and energy consumption, minimize environmental pollution through process improvement and facility investment, and at the same time, try to produce the best product quality.

Environment

& Energy

Management

Policy

& Energy

Management

Policy

Dongkuk CM practices customer satisfaction and human-centered management, based on the management philosophy of “contributing to cultural development through steel.”

To create a safe and pleasant work environment and realize "a company that protects the safety and health of all workers," we implement the following:

One. We recognize the environment and energy as the top priority in management

One. We ensure workers' participation and consultation in environment and energy management activities.

One. We comply with relevant laws and agreements, and create an eco-friendly workplace.

One. We identify the potential occurrence of environmental pollution in advance and prepare countermeasures.

One. We reduce energy consumption and minimize environmental pollution through efficient use of resources.

One. We build social trust by strengthening communication with stakeholders.

One. We recognize the environment and energy as the top priority in management

One. We ensure workers' participation and consultation in environment and energy management activities.

One. We comply with relevant laws and agreements, and create an eco-friendly workplace.

One. We identify the potential occurrence of environmental pollution in advance and prepare countermeasures.

One. We reduce energy consumption and minimize environmental pollution through efficient use of resources.

One. We build social trust by strengthening communication with stakeholders.

This policy is announced to all stakeholders, and all executives and employees continuously strive to improve safety and health management

June 1, 2023

Chairman Park Sang Hoon

Chairman Park Sang Hoon

Environment

& Energy

Management

System

& Energy

Management

System

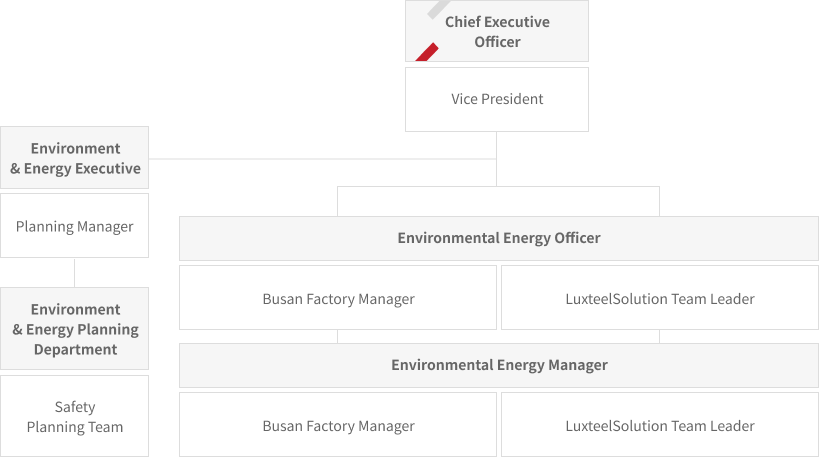

Dongkuk CM conducts thorough management based on the environment and energy management system to prevent environmental pollution that may occur during production activities and minimize damage.

Environment

& Energy

Organizations

& Energy

Organizations

Introduction of Korea’s first eco-arc electric furnace that maximizes energy efficiency and reduces greenhouse gas emissions

- Installation of SCR (Selective Catalytic Reduction, 4th Generation) and low NOx burners (3rd Generation): A 38% reduction in nitrogen oxide (NOx) emissions.

- Installation and operation of 18 units of real-time monitoring equipment, TMS (Tele-Monitoring System), for thorough monitoring of air pollutant emissions.

Introduction of the hot charge production method that increases energy efficiency by operating the heating furnace flexibly

- Reduction of water pollutants through physical-chemical, biological, and advanced treatment processes.

- Thorough management of treated water quality through real-time measurement and monitoring (Operation of 2 units of TMS).

Installation of solar power facilities

- Installed 2.7MW solar power generation facility in Busan Factory in Oct. 2014

- Pollutants/Greenhouse gas emission “Zero” facility

Application of bio boiler, a representative technology for eco-friendly clean energy

- After the operation of the boiler with eco-friendly fuel in Aug. 2017, greenhouse gas emission reduced by14,000 tCO ₂eq annually.

Brochure

Brochure

Advertisement

Advertisement

Contact Us

Contact Us